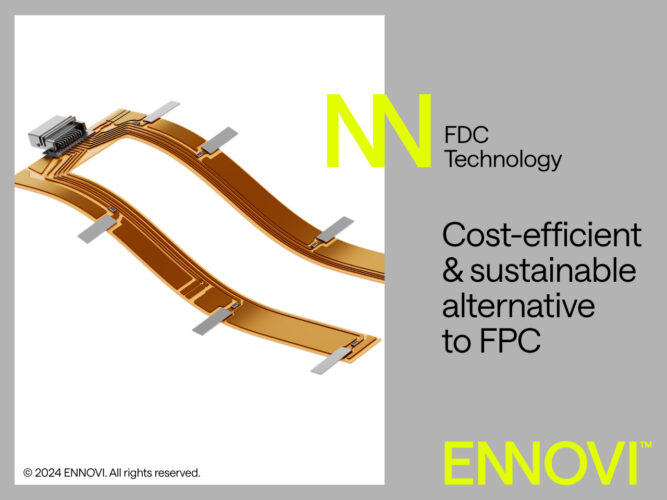

ENNOVI, as a leading provider of mobility electrification solutions, has developed an innovative and sustainable approach to producing flexible circuits for low voltage signals in electric vehicle (EV) battery cell contacting systems. Traditionally, flexible printed circuits (FPCs) have been used in these systems, but they are the most expensive component in the current collector assembly. ENNOVI's flexible die-cut circuit (FDC) technology offers a cost-effective and environmentally friendly alternative, with a streamlined manufacturing process and continuous reel-to-reel production.

The production process for FPCs involves multiple stages of batch photolithography to etch copper traces onto the flexible circuit. This process uses corrosive chemicals to remove unwanted copper, and the extraction and recycling of the waste copper from these chemicals is time-consuming and energy-intensive. In contrast, the die-cutting process used in FDC technology allows for instant recycling of the copper, making it a more sustainable choice compared to chemical etching.

FDCs have several advantages over FPCs. While FPCs have size limitations of 600x600mm, FDCs can be manufactured without length restrictions due to the reel-to-reel production method. Under certain design considerations, FDCs can provide similar performance characteristics to FPCs. Rigorous in-house testing has confirmed the dimensional accuracy, thermal shock resistance, trace resistance, temperature rise, insulation resistance, and high voltage performance of FDCs.

Gustavo Cibrian, Product Manager, Energy Systems, at ENNOVI, highlights that adopting FDC technology for flexible circuits aligns with the company's vision of creating a sustainable battery value chain for EVs. By offering a cost-effective and time-efficient solution, ENNOVI empowers battery manufacturers to achieve their cost, time, and performance objectives in current collector assembly design.

For more detailed information about ENNOVI's FDC technology competency, please visit their website at https://ennovi.com/fdc-technology/

About ENNOVI:

ENNOVI is a global leader in designing and manufacturing customized interconnect and high-precision system solutions for electric vehicles. As a Mobility Electrification Solutions Partner, ENNOVI is fully dedicated to serving the mobility market and is capable of rapidly addressing the needs of EV OEMs worldwide in terms of product design, manufacturing processes, and end-to-end solutions. Headquartered in Singapore, ENNOVI operates with social responsibility and strives to minimize its environmental impact across its 15 global sites. With over 10,000 employees, ENNOVI is committed to accelerating the electrification of the EV market.