About Us

HomeAbout Us

Company

Profile

Founded in 2006 and located in Shenzhen, China Chipmall.com is a world-renowned electronic component distribution platform, distributing electronic products from more than 500 branded manufacturers with a variety of semiconductor products, passive devices,interconnected devices and electromechanical components.

Chipmall.com always adheres to the principle of "Quality first, customer first" and has been recognized by many customers.

In the future, we will continue to improve the company's processes and services, committed to meet the continuous growth of customer needs, to become your most trusted partner.

OUR SERVICE

Service

Sourcing

Promotion

Inventory

Management

LET'S US LEARN ABOUT

THE CORPORATE CULTURE

Create value with service, establish authority with professionalism and win the future with integrity.

Our Vission

Our Vission Our Mission

Our Mission Core Values

Core ValuesQUALITY

ASSURANCE

Chipmall realized there are many fake parts in the global electronics supply chain.which would have caused serious issues and bad consequences for customers.Therefore, we firmly believe that only by obtaining sources from authorized suppliers with enhanced quality test could it be safe and reliable.

Read More

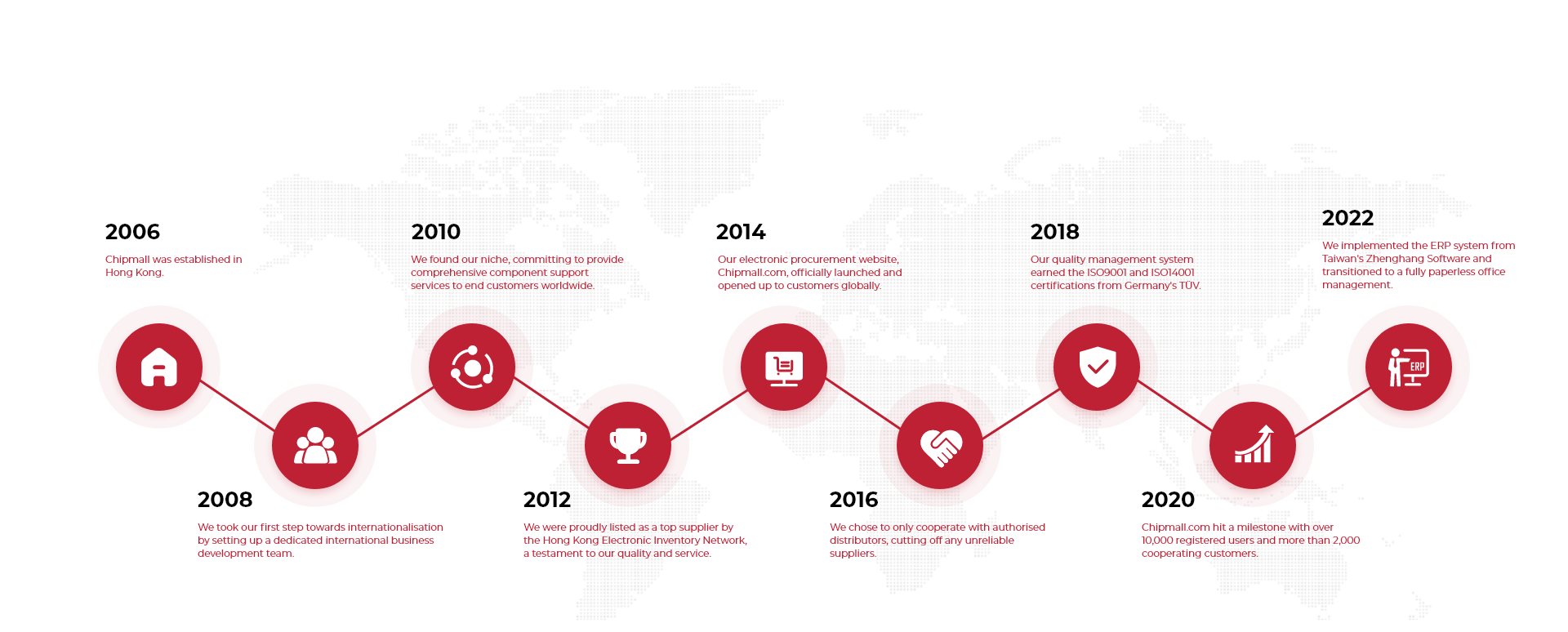

Milestone

OUR TEARMS